Precision

in Production

From Bill of Materials to Finished Goods—Gain complete visibility and control over your entire manufacturing process.

Eliminate Factory Blind Spots

Manufacturing is chaos management. Stop juggling disconnected spreadsheets and start orchestrating your shop floor with a centralized brain.

The Challenge

- Disconnected data silos (Inventory vs Accounting)

- Unpredictable machine downtime

- Material shortages halting production

- Inaccurate costing and margin analysis

The ERPNext Solution

A unified platform where a change in inventory instantly reflects in accounting, and a sales order triggers production planning.

Defining the Product: BOM

Multi-level Bills of Materials that handle complex structures, sub-assemblies, and scrap management with ease.

Data-Driven Manufacturing

Every component is tracked. Scrap rates are calculated automatically. Versions are managed with change logs.

Strategic Planning & MRP

From sales forecast to production schedule in one click. Prevent stockouts and overproduction.

Sales Order

Customer places order for 50 Drones.

MRP Engine

System checks inventory & calculates shortages.

Production Plan

Work orders & Material Requests created.

Shop Floor Real-Time View

Live monitoring of workstations, job cards, and operations.

CNC Station 01

RunningAssembly Line A

MaintenanceFinal Testing Bay

RunningReady to optimize your production line?

Join 5,000+ manufacturers who trust ERPNext to deliver quality products on time, every time.

Schedule a DemoExecution: The Work Order

The central document that signals the warehouse to release materials and the floor to begin work.

The Conductor

Signals the warehouse to release materials and the floor to begin work.

Stock Reservation

Reserve specific batches (e.g., Lithium Cells) against a Work Order.

Back-Flushing

Upon completion, the system automatically consumes raw materials based on the BOM.

Granular Control: Job Cards

Track actual time spent by specific employees or machines with precision.

Real-Time Tracking

Track actual time spent on specific operations like "Precision Milling".

Efficiency Analysis

Compare Planned Time vs. Actual Time to identify training needs.

Operational Costing

Actual labor costs are captured and added to the final product valuation.

Integrated Quality Inspection

Don't let defects leave the floor. Enforce checks at incoming receipt, WIP, or finished goods.

Gatekeeping

Mandatory stops in the workflow for quality verification.

Standardized Templates

Define acceptance criteria (e.g., Variance < 0.5%) for consistency.

Block Non-Conformance

Automatically block inventory that fails inspection from being shipped.

Traceability: Serial & Batch Management

Full lifecycle tracking from procurement to sale. Know exactly which batch of batteries went into which drone.

Serialized Inventory

Assign unique IDs to high-value goods for warranty tracking and individual history.

Batch Control

Prevent expired materials (like chemicals or batteries) from being used in production.

Full Lifecycle

Track every component from the supplier's dock to the customer's hands.

Extended Supply Chain: Subcontracting

Seamlessly handle tasks like painting or galvanizing sent to external partners.

Core Competencies

Focus on what you do best and outsource the rest without losing visibility.

Material Transfer

Track raw materials supplied to the vendor via Subcontracting Orders.

Auto-Reconciliation

Automatically consume supplied raw materials and record service charges upon receipt.

Real-Time Financial Integration

Every stock movement creates a corresponding accounting entry in real-time. No more end-of-month surprises.

Perpetual Inventory

Stock accounts are updated instantly upon receipt, delivery, or production.

True Costing

Valuation includes Material Cost + Landed Costs (Freight/Customs) + Operational Costs (Labor/Power).

Valuation Methods

Supports FIFO (First-In, First-Out) and Moving Average for precise profit calculation.

Data-Driven Decision Making

Turn shop floor actions into actionable insights.

Production Analytics

Visualize trends in production volume and identify delay rates over time.

Downtime Analysis

Identify exactly which machines or workstations are causing bottlenecks.

BOM Stock Reports

Instantly see if you have enough raw materials to build a specific batch before starting.

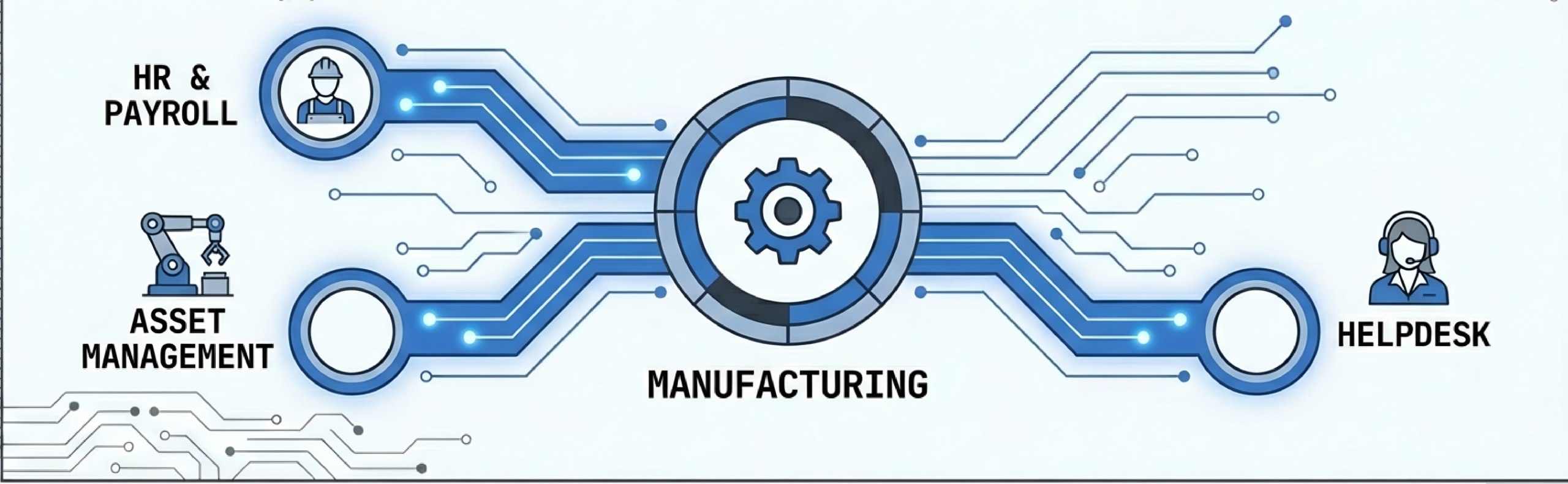

The Unified Ecosystem

Manufacturing doesn't happen in a silo. Connect your floor to HR, Maintenance, and Support.

Asset Management

Track depreciation and schedule maintenance for your high-value machinery.

HR & Payroll

Link employee timesheets from the Job Cards directly to payroll processing.

Helpdesk Support

Convert customer issues into tickets linked directly to the specific serialized item they purchased.

Streamline Your Shop Floor Today

Complete Visibility. Total Control.

ERPNext: The operating system for modern manufacturers.